Housebuilder magazine (Oct 2006) has published a short article by Graeme Owen of BSRIA about how new homes are doing in the airtightness stakes. The tests were carried out before the new requirement for airtightness testing came into effect but nevertheless the results are dramatic.

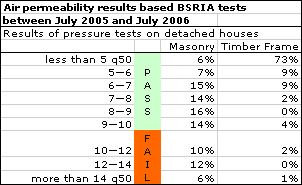

Housebuilder magazine (Oct 2006) has published a short article by Graeme Owen of BSRIA about how new homes are doing in the airtightness stakes. The tests were carried out before the new requirement for airtightness testing came into effect but nevertheless the results are dramatic. The pass rate, set out in Part L1A, is 10m3 per hour per m2 of heated envelope at 50 Pascals of pressure, which is such a mouthful that it is now being reduced to 10 q50. Energy wonks don’t regard this as very demanding: the best practice low energy homes score as low as 1.5 q50. Nevertheless, many of our new homes struggled to make it through the new hurdle.

All but 3% of timber frame homes achieved a pass and as many as 73% of timber frame homes tested achieve a score of 5 q50 or less. In contrast, 28% of masonry homes failed the new standard and only 6% met a score of 5 or less.

Why the huge difference? Well there is a clue given in the article. Apparently, the masonry build data was further broken down into houses which were wet-plastered and those which were dry-lined, using plasterboard stuck on with dot and dab. The wet-plastered houses achieved a pass rate comparable with timber frame: the dry-lined homes most certainly didn’t. To build airtight with dry-lined walls, you need to seal around all the edges, something that has very rarely been done till now.

If you want to download BSRIA’s guide to airtight building and the new testing regime, click right

here

No comments:

Post a Comment